E-900 XLT Hot Tube

Tank Capacity Maximum -- 200

Tank Capacity nominal -- 120

Weight -- 3,140

120 Gallons per hour

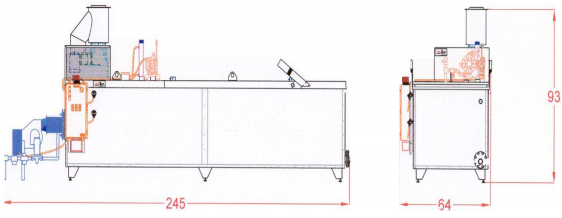

Length -- 190"

Width -- 64"

Height -- 93"

Standard Features

- Tank construction -- 10 gauge, 316L stainless steel construction

- Heat exchange tube -- 10 gauge, 316L stainless steel construction

- Access and blower lid -- stainless steel for all wetted parts

- Insulation -- 2” foil backed, 850°F, .30 conductivity, .043 SI units

- Exhaust blower housing -- heavy gauge, tig welded stainless steel

- Impeller -- self-cleaning backward inclined radial blade design

- Stack connection -- 14” I.D. flanged

- Blower motor -- 3 hp, 3ph, 3450 rpm

- Power burner -- forced draft burner, FM rated with full modulation

- Fluid transfer pump -- air operated diaphragm pump, 1” FPT

- Control panel -- NEMA 4 rated enclsoure, industrial duty

- Fluid level control -- float actuated ball valve

- Fluid level sensors -- float actuated microswitches, high/low level

- Coalescing filter -- framed galvanized steel mesh at blower inlet

- Clean out -- 4” flange with eccentric reducer at 2” FPT

- Weir -- built in for easy skimming of floating oils

- Belt driven blower -- eliminates transference of vibration and heat

- Pillow block bearings -- heavy duty, greasable for long life

Optional Features

- Special tank/tube construction

- Double wall stacks

- Remote fluid level sensors

- Overspray foam control

- Automation Package

- Skimmer/Sludge Pump

- Remote tank oil sensing

- Power wash clean out ports

- Rectangular clean out

Safety Features

- Industrial safety disconnect at the unit

- Air-cooled, counterweighted access lid

- Safety circuitry and manual reset

- Flame safety monitoring burner flame

- Safety cage around hot moving parts

- Fluid temperature monitor

- Heat exchanger temperature monitor

- Redundant safety and level controls